Potting compound

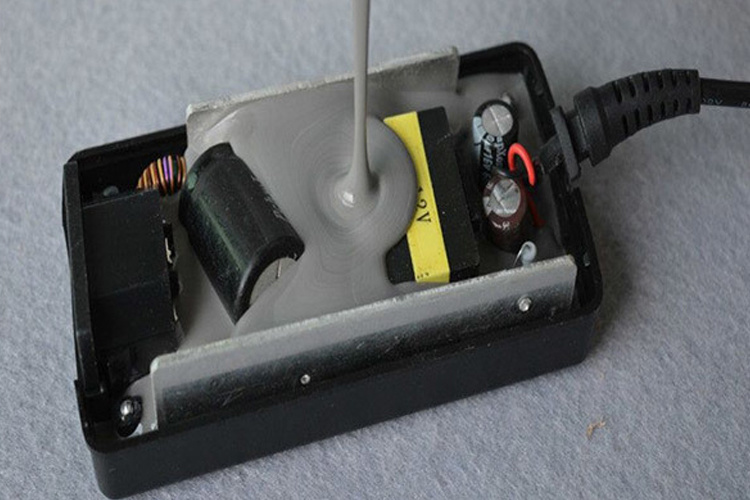

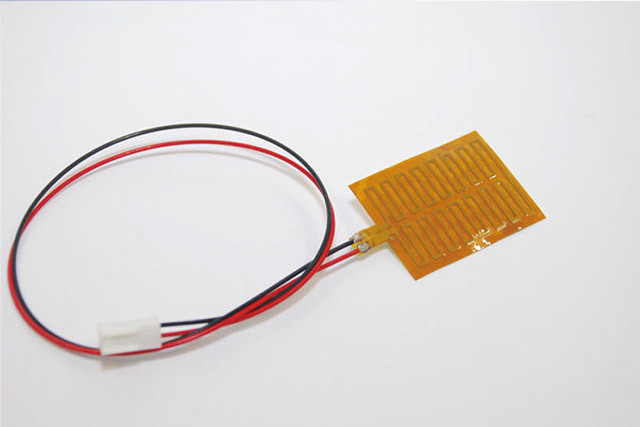

Products used in: communication equipment, network terminals, storage equipment, LED lamps, consumer electronics, power supply devices

Security equipment, etc.

Key words:

Classification:

Description

LSG-307AB is a low-density, thermally conductive organosilicon potting compound that cures at room temperature/heat. This two-part elastic silicone rubber is designed for potting and protecting electronic products under demanding conditions.

LSG-307AB low-density thermally conductive potting adhesive uses new technology and cures well without heating. When using, mix A/B components in a 1:1 (mass/volume) ratio. The product will fully cure within a certain time to form an elastic buffer and thermally conductive material with the following characteristics:

▶ Resistance to moisture, dirt, and other atmospheric components

▶ Reduces mechanical stress and tension caused by mechanical, thermal shock, and vibration

▶ Easy to repair

▶ Solvent-free, no curing byproducts

▶ Stable mechanical and electrical properties at -50℃-200℃.

▶ Excellent flame retardancy

| Test Item | Test Standard/Condition | Unit | AComponent | BComponent | ||

| Appearance | Visual Inspection | / | Gray, viscous | White, viscous | ||

| Viscosity | GB/T 10247-2008 | mpa·s | 8000±500 | 6500±500 | ||

| Density | GB/T 13354-92 | g/ml | 1.28±0.05 | 1.30±0.05 | ||

| Mixing Ratio | / | Mass/Volume | 100 | 100 | ||

| Mixed Viscosity | GB/T 10247-2008 | mpa·s | 7000±500 | |||

| Working Time | 25℃ | H | 1 | |||

| Surface Dry Time | 25℃/70℃ | H | February 4 | |||

| Full Cure Time | 25℃/70℃ | H | 4 | |||

| Cured Technical Parameters | ||||||

| Hardness | ShoreA | 48±5 | ||||

| Thermal Conductivity | GB/T10297-1998 | W/m·k | ≥0.8 | |||

| Flammability Rating | UL94 | / | V0 | |||

| Dielectric Strength | GB/T 1693-2007 | KV/mm(25℃) | ≥25 | |||

| Dielectric Constant | GB/T 1693-2007 | (1MHz)(25℃) | ≥2.5 | |||

| Volume Resistivity | GB/T 1692-92 | Ω·m | ≥1.0×1014 | |||

Color, working time, and hardness can be adjusted according to user conditions.

Operating Instructions

(1) If the material is left for too long, sedimentation will occur. Before use, please stir A and B components separately and then mix them.

(2) Stir in the same direction as much as possible to avoid introducing more air bubbles. The material on the edges and bottom of the container should also be stirred evenly to prevent incomplete curing.

(3) After pouring onto the product, vacuum again to remove air bubbles, which can improve the overall performance after curing.

(4) Low temperatures will slow down curing. If necessary, heat curing can be used.

(5) Contact with compounds containing N, S, P elements and some heavy metal ion compounds (Sn, Pb, Hg, Bi, As, etc.) will cause curing difficulties or incomplete curing.

Packaging Specification

Component A: 25kg/barrel Component B: 25kg/barrel

Storage and Transportation

1. Storage period: 12 months below 25℃ (If left for too long, sedimentation will occur. Stirring evenly before use is acceptable; this is not a product quality issue).

A and B components should be stored in a sealed, dark, and cool place.

Related Products

Online consultation