Welcome to Yiwu Leifeng Electronic Technology Co., Ltd. website

Principle of Heat Conduction

With the rapid development of microelectronics technology, the size of chips is getting smaller and smaller, while the computing speed is getting faster and faster, and the heat generation is also getting larger and larger. Statistics show:

1. For every 2℃ increase in operating temperature, reliability will decrease by 5-10%.

2. Transmission signal delay, processing speed reduction, idle power dissipation increase, exceeding the operating temperature range will directly damage the chip.

Therefore, considering the above impacts, R&D will consider the following two principles during design:

1. Reduce heat generation, i.e., use better control methods and technologies, such as phase-shift control technology, synchronous rectification technology, etc. In addition, use low-power devices, reduce the number of heat-generating devices, increase the width of thick printed lines, and improve power efficiency.

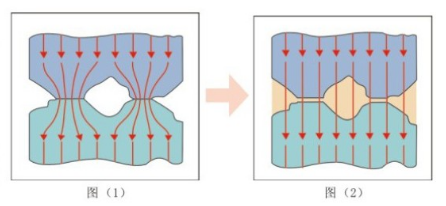

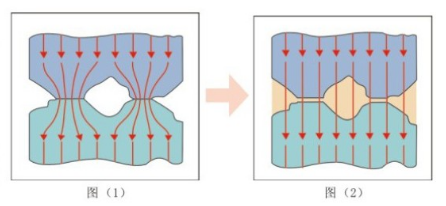

2. Enhance heat dissipation, i.e., use conduction, radiation, and convection technologies to transfer heat. However, even with the finest heat sinks and aluminum substrates, gaps inevitably appear (as shown in Figure 1). Due to the roughness, the actual contact area is only about 10% of the total area, with the remaining 90% being air, and air has poor thermal conductivity, with a thermal conductivity of only 0.02 W/m.K. Therefore, it is necessary to use thermally conductive materials to fill the gap between the heat source and the heat sink (as shown in Figure 2) to increase the contact area between the two to conduct heat, making the heat conduction speed uniform and maximizing the transfer to the heat sink.

Yiwu Leifeng Electronic Technology Co., Ltd

Address: No.1, Huajin Road, Houzhai Industrial Zone, Yiwu City, Zhejiang Province

Telephone: +86-579-85680790

E-mail: sales@leifeng-tech.com

Fax: +86-579-85681397

%E7%AC%AC%E4%B8%80%EF%BC%8C%E6%9C%80%EF%BC%8C%E4%BC%98%E7%A7%80%EF%BC%8C%E5%A2%9E%E5%BC%BA%EF%BC%8C%E4%B8%80%E6%B5%81%EF%BC%8C%E5%8D%93%E8%B6%8A%EF%BC%8C%E9%A2%86%E5%85%88%EF%BC%8C%E5%85%88%E8%BF%9B%EF%BC%8C%E5%BC%95%E9%A2%86

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home