What is a thermal pad?

Release time:

2021-08-25

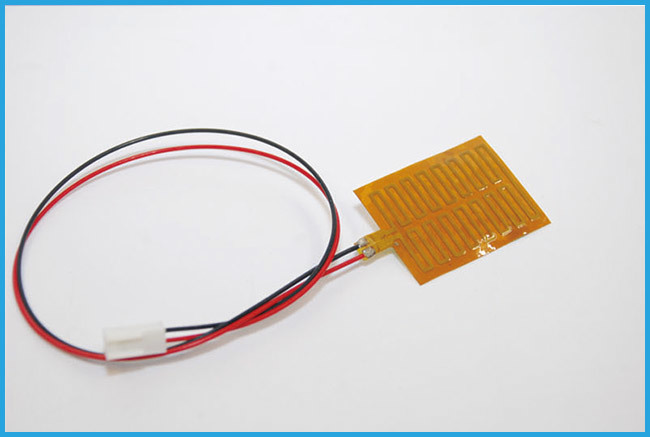

Thermal PadA high-performance gap-filling thermal material, mainly used for interface transmission between electronic devices and heat sinks or product housings. It has good viscosity, flexibility, compression performance, and thermal conductivity. During use, it completely expels air between the electronic source and the heat sink to allow for full contact. The cooling effect is significantly increased.

Thermal PadWith thermal conductivity and a high level of voltage resistance, it is an alternative product to replace thermal grease. The material itself has a certain degree of flexibility, which can effectively cooperate between power devices and heat aluminum or mechanical housings, achieving good heat conduction and heat dissipation purposes. It meets the requirements of the 21st-century electronics industry for thermal materials and is a good product for a binary thermal system that replaces thermal silicone grease and mica film. In the industry, it can also be called thermal silicone sheet, thermal silicone pad, thermal silicone plate, insulating heat conduction plate, soft heat conduction pad, etc.

Thermal PadOverview:

As electronic devices continue to integrate more powerful functions into smaller components, temperature control has become one of the most important tasks in design. That is, under the circumstances of shrinking architecture and increasingly smaller operating space, how to effectively eliminate the greater amount of heat generated by higher unit power. Designers have been working to improve the CPU speed and processing power of various servers, which requires microprocessors to constantly improve heat dissipation performance. However, other applications (such as video game consoles, image devices, higher-performance digital applications that require support for high-definition images) also require stronger computing power. Therefore, chip manufacturers are more concerned than ever about thermal materials (thermal pads) and other technologies that can remove excess heat, which has a counterproductive effect on the stability and lifespan of the components. It is understood that the operating temperature of the joint has a great impact on the durability of the circuit (transistor), and a small reduction in temperature (10C-15C) can double the lifespan of the device. [1] The lower the operating temperature, the shorter the signal waiting time and the faster the processing speed. In addition, the lower the temperature, the less idle power consumption (power consumption), thereby reducing the total power consumption.

Thermal PadMimicking from an engineering perspective, making the irregular surface of the material consistent, using high-performance thermal conductive materials, eliminating air gaps, improving overall thermal transfer capabilities, and enabling components to operate at lower temperatures.

When selecting thermal pads, the size and thermal conductivity of the thermal silicone sheet should be determined according to the specific heat source (such as CPU, memory, modem module, etc.). This is a TIF thermal silicone sheet recommended for cooling routers; it has high compressive strength and strong viscosity, does not require the separate use of adhesives, and various thicknesses can be selected.

In the main chip area of the router, in addition to heat dissipation and shielding issues, thermal pads mainly involve attaching a shielding film to the chip and adding thermal conductive gel between the shield and the chip to fill the gaps.

Related Information